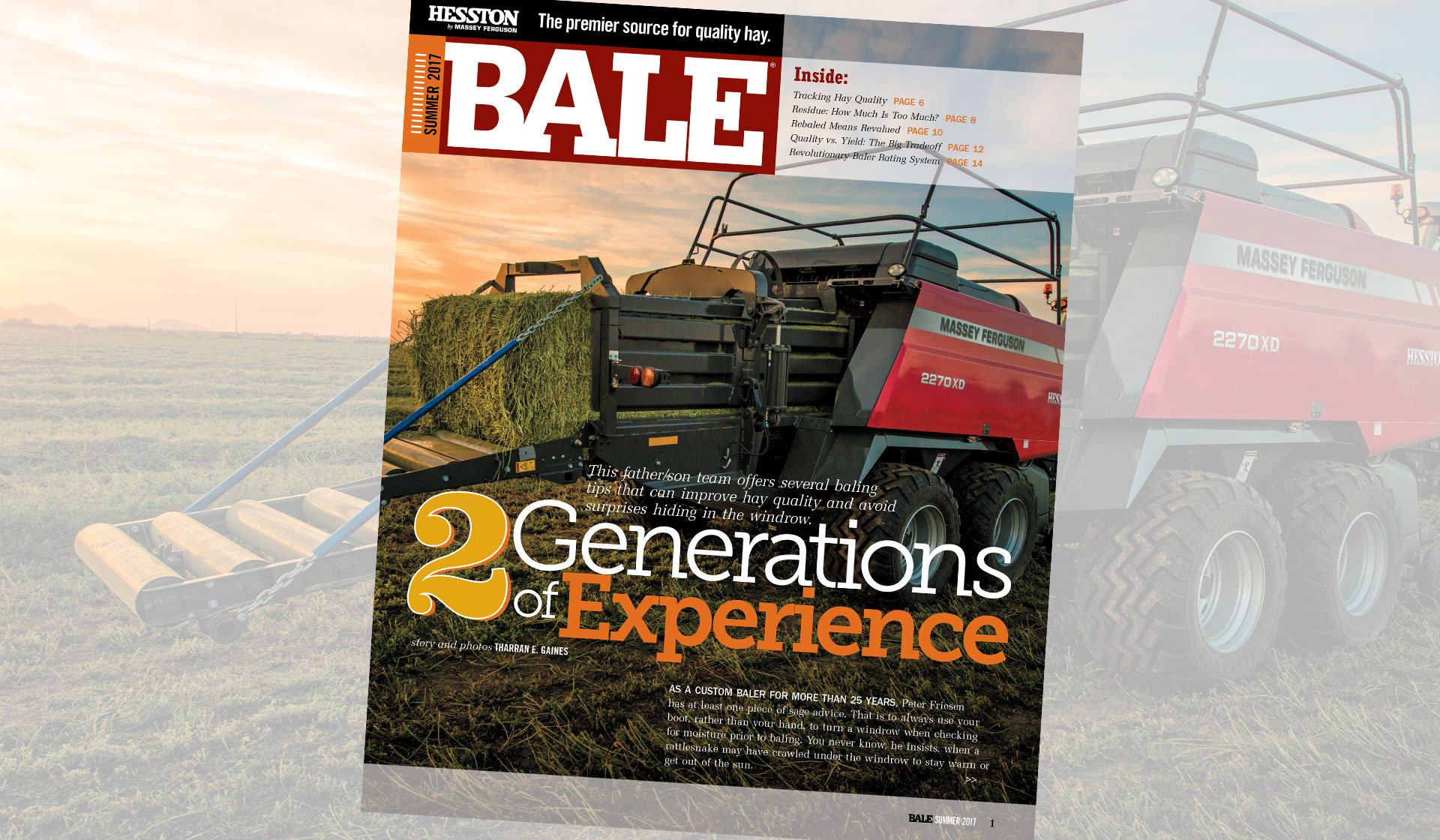

Two Generations of Experience

This father/son team offers several baling tips that can improve hay quality and avoid surprises hiding in the windrow.

By Tharran E. Gaines

As a custom baler for more than 25 years, Peter Friesen has at least one piece of sage advice. That is to always use your boot, rather than your hand, to turn a windrow when checking for moisture prior to baling. You never know, he insists, when a rattlesnake may have crawled under the windrow to stay warm or get out of the sun.

Father-and-son team, Peter (left) and Franz Friesen, put up between 30,000 and 40,000 bales per year.

For those who farm, especially near Liberal, Kansas, which Peter calls “home base,” that’s a meaningful recommendation. Yet, he’s picked up plenty of other tips during his quarter-century in the business that can benefit producers in venom-free areas as well.

With the help of two full-time employees, Peter Friesen and his son Franz “Frank” Friesen operate a custom hay baling business that puts up between 30,000 and 40,000 bales of alfalfa, wheat straw and miscellaneous forage per year throughout southwest Kansas and northern Oklahoma.

“I bought my first Hesston big square baler approximately 16 years ago,” says Peter, noting that he’s actually been in the custom baling business since the early ’90s. “When I first started, I was putting up small square bales. It wasn’t until I bought a Hesston 4910 that I got into big square bales.”

Today, after trading balers every year or two, the family is using two Hesston by Massey Ferguson® 2270XD balers pulled by a matching pair of Massey Ferguson® 7624 tractors. The combination, according to Franz, has been amazing. In fact, the tractor/baler combination has been one of the keys to bale quality, as the younger Friesen explains while sharing some of his and his dad’s tips on baling alfalfa.

Maintain consistent bale flake size

“We try to keep the flake count consistent from one bale to another and the flake thickness consistent within ¾ inch from one flake to the next,” he says. “This not only results in a better-quality bale, but it helps with hauling and stacking later on, since all the bales share the same size and density.” In effect, he adds, they stack like bricks.

The Friesens rely on the pairing of Hesston balers and Massey Ferguson tractors, and the CVT of the latter, to precisely manage crop intake and, ultimately, flake size.

To manage flake size, the Friesens rely on bale length monitors they have installed on their balers. As an attachment to the star wheel on the bale chamber, it shows the size of each flake and the progression of each bale as it leaves the bale chamber. Based on that information, the Friesens will increase or decrease ground speed, using the Dyna-VT™ continuously variable transmission (CVT) in their Massey Ferguson tractors, to precisely manage crop intake and, ultimately, flake size. Franz says they also like to adjust ground speed and crop intake so that one stroke of the baler plunger equals one bale flake.

On a related note, Alexandre Rocateli, forage systems Extension specialist at Oklahoma State University, insists the baler needs time to press the forage mass into the bale. The faster the baler, he relates, the lower the forage packing and the softer the bale. The ground speed and the baler pickup speed need to be synced to produce the highest quality bales.

Monitor bale weight

Friesen and crew also watch the monitor for changes in bale weight. As each bale passes through the bale chute, the scales kit they installed on each baler provides an approximate weight.

“If we suddenly see the bale weight increase by 100 pounds or so, we know the moisture is coming on and we need to decrease the load setting on the plunger,” Franz explains. “Say, for example, we start off baling in the evening with the plunger set at 345 pounds, which gives us a 1,400-pound bale at 12 to 13% moisture,” he continues, noting that this is typically where they start with alfalfa. “Once we see the bales are getting heavier, we’ll back off on the plunger load to the point it might be 240 to 255 by the time we stop at 15 to 16%.”

Rocateli notes that even though producers can monitor the bale density from the tractor cab, it is recommended to manually inspect the bales on occasion. “Poke the bales and feel how tight they are,” he says. “As a general rule, you should not be able to stick your finger into the bale.”

Moisture is critical

While it’s important to know when to stop baling for the day, Franz says it’s equally important to know when to start.

“I’ve seen studies, which we can confirm, that the nutrient loss from baling at a low moisture level is far less than the loss that occurs when raking hay at a low moisture level,” he says, noting that the nutrient loss from raking hay that’s too dry can be as high as 30 to 40%.

As Rocateli explains, the key to producing quality alfalfa is to retain the nutrient-rich leaves. Hence, raking at the proper moisture level and minimizing horizontal movement, which happens during raking, is critical to preserving hay quality and improving the efficiency of the baling operation.

Watch the weather

One of the tools the Friesens have found invaluable in recent years has nothing to do with farm equipment. It’s the smartphones they use on a regular basis to check the weather report, especially humidity, wind speed and wind direction.

“We’re always looking at the humidity and the forecast for the next few days,” Franz says. “We’ve learned that the humidity also depends on the wind speed and direction. The wind from the southwest, for example, is a lot drier than wind from the east, and that alone can affect our starting time.

“It also depends on the amount of moisture in the ground below the windrow,” he adds. “In effect, the windrow has its own climate; but in general, the best time for us to bale is around sunrise and the first few hours in the morning.”

Although the Friesens don’t use hay preservatives, Rocateli says a preservative can be used when baling forage that contains moisture between 20 and 30%.

“In this forage moisture range, the preservatives will lower the forage pH inhibiting aerobic microbial activity,” he says “However, do not bale if forage moisture is higher than 30%.”