Economics of residue management

With increased plant populations and yields in the field, comes more residue to deal with.

While corn stover provides the soil with recycled nutrients, increased organic matter and erosion protection, if not managed properly it can cause issues with planting and emergence the following year. Today’s modern corn hybrids not only have been bred to resist stalk diseases and insects, but are also receiving a higher level of management through increased plant populations, fungicide applications to control disease and in season nitrogen applications; all of which lead to lots of tough residue to breakdown after harvest. A heavy residue mat lying on the soil surface provides insulation to create a cold, wet environment for seed come spring.

Obviously, there are pros and cons to each tillage type and sometimes you don’t have much of a choice if your fields are prone to soil loss. However, no matter your tillage practice, you still have an opportunity to manage your residue. When it comes to residue, more is not always better, but having none can also be a problem.

Striking the right balance

Differences between tillage types

Strip Till

With strip till, residue is mostly left undisturbed except for strips about one third of the row width. Doing this allows for some warming and drying of the field that it would not receive from no-till alone. Studies have shown that strip tilled fields provide the same yield as conventional tillage. This is because the strip has very similar characteristics to a conventional tilled field that provides a warm moist place for the seed, unobstructed rooting, while benefiting from residue cover between the rows in the summer which helps reduce moisture losses to evaporation.

Vertical Tillage

Residue with vertical tillage is sized by coulters or low concavity disc blades. Units with no or low gang angles, less than eight degrees, do not lift or turn sufficient amounts of soil. This leaves the residue on the surface prone to wind and/or water erosion. Vertical tillage tools operating with increased gang angles featuring fluted blades lift soil and are better able to anchor crop residue into the soil to prevent residue migration. These tools also provide a superior weed kill.

Residue is lifted up by vertical coulters, but soil is not lifted or turned over. This does allow for better warming and drying versus no-till, but this also means that the stalks can more easily be blown or washed away. This type of tillage will not destroy weeds, or incorporate fertilizer.

Conventional Tillage

Conventional tillage consists of tools that engage the soil across the entire width of the tillage tool. Normally conventional tillage would include a fall pass after harvest of a tool operating at a deep depth to remove soil compaction and incorporate crop residue. This would be followed in the spring with one or more secondary tillage passes to establish a seedbed prior to planting.

No-till

Even if you do not plan to till your fields, you can still help with residue by making sure your combine is evenly distributing straw and chaff. Pioneer® Hybrids have some great tips on how to control residue with your combine:

- Check residue distribution pattern on new equipment and purchase residue spreading attachments if necessary.

- Change pulleys to increase the speed of straw spreaders to achieve wider distribution.

- Keep blades of choppers sharp to ensure proper cutting of stalks.

- Change the treatment at the header so it chops and shreds corn stalks more.

Cost Comparison

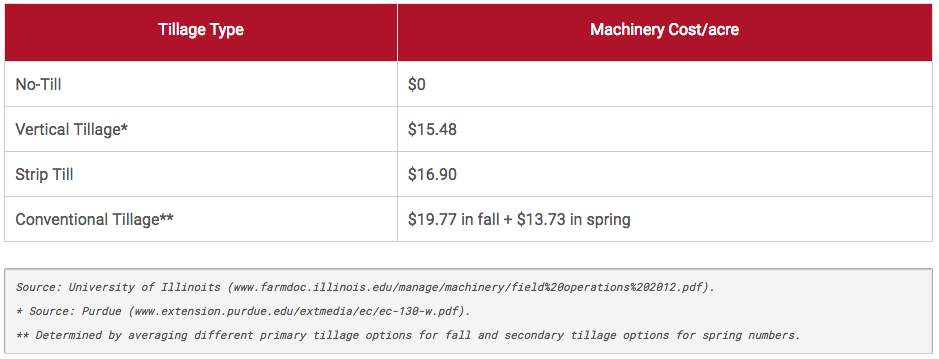

Tillage Cost

Herbicide Costs

When no-till or reduced tillage (strip and vertical) is practiced, herbicide usage tends to go up since the weeds are not being controlled by tillage. In reduced tillage operations, a farmer might have to spray two to three times to control weeds, whereas in conventional tillage, it would be limited to one or two.

Returns

When it comes to tillage and crop yield, it’s really location that matters. The midwest typically sees a yield advantage to conventional tillage, but in places where temperatures are warmer and water is more limited, such as the south or west, no-till operations tend to see the yield advantage.

For midwest farmers, the upside to conventional and strip tillage systems is the ground can warm and dry more quickly than with the reduced tillage systems. Generally, this means farmers using that practice can either work ground or plant sooner than farmers with reduced tillage. Since these two tillage practices typically make the ground 10% drier, that means you have a bigger window to get your seed in the ground.

Pros & Cons

No Till

Pro: Best for erosion control and retaining soil moisture. Increased organic matter on the top of soil, and requires minimal machinery and labor costs.

Con: Must use herbicide as main weed management; field is colder and wetter in the spring, which lowers your planting window. Harder to incorporate manure and fertilizers. Can result in uneven emergence due to soil temperature fluctuations and residue in the way.

Vertical Tillage

Pro: Helps with erosion control and retaining soil moisture. Increased organic matter on the top of soil. Breaks up stalks slightly.

Con: More cost than no-till, could be some soil erosion, more compaction risk than no-till.

Strip Till

Pro: Less soil erosion due to wind and water runoff, less machinery cost than conventional. Soil in seed path tends to be drier and warmer. Yields similar to conservation till.

Con: More cost than no-till, weeds could be spread down the field somewhat, but less than conventional. Requires specific tillage to match up with planter, more compaction risk than no-till.

Conventional

Pro: Machinery is easy to come by and can be used in almost all crop types. Tillage controls the weeds so there may be fewer problems with weed resistance. Soil warms faster and yield is generally the highest in this category.

Con: Machinery cost (fuel, labor, etc.) is high. With increased tillage comes increased passes in a field, which leads to a higher compaction risk and increased risk of erosion.

Conservation Tillage

Pro: Less cost than conventional tillage and leaves residue on top to deter erosion. Also, sizes material for better decomposition. Yield is usually similar to conventional tillage.

Con: Less effective in burying residue and/or weeds.

Things to consider

Strip till can be done during anhydrous application or by itself. These tillage tools need to line up with planter tools in regard to row width. One of the cons of this system—additional management required to be effective with this system. Row guidance is very important as is effective fertilizer management.

Tillage practices vary over the country and what is best in one region may work well in another. In some areas, crops yield better in no-till situations than conventional till, while other areas have crops that thrive better in tilled soil. AGCO has a complete line of tillage equipment to help farmers be successful with whatever tillage system works best for their farming operation.