Tracking Hay Quality

New relative feed value (RFV) calculators and tracking systems allow producers to sort bales in the field.

By Tharran E. Gaines | Photos By Brett Deering

WEB EXCLUSIVE: To learn more about the HayBoss G2, RFV calculator, and other related tools, download a free guide. CLICK HERE >>

Not all bales are the same.

Despite his best efforts to ensure the production of top-quality alfalfa, Jeramy Whitaker, farm manager for the 1,000-cow Whitaker Dairy, certainly recognizes that lack of consistency as fact. Whitaker knows from experience that hay quality can vary from one side of the field to the other, and with the time of day the hay was baled.

In the past, that often meant sorting through bales as they were being fed, sending the higher-quality bales to the milking herd and saving back the lower-quality bales for dry cows and heifers. Even then, they couldn’t be sure what they had without taking core samples and sending them to a lab for analysis. Selection was always based somewhat on bale appearance.

Easier, More Precise

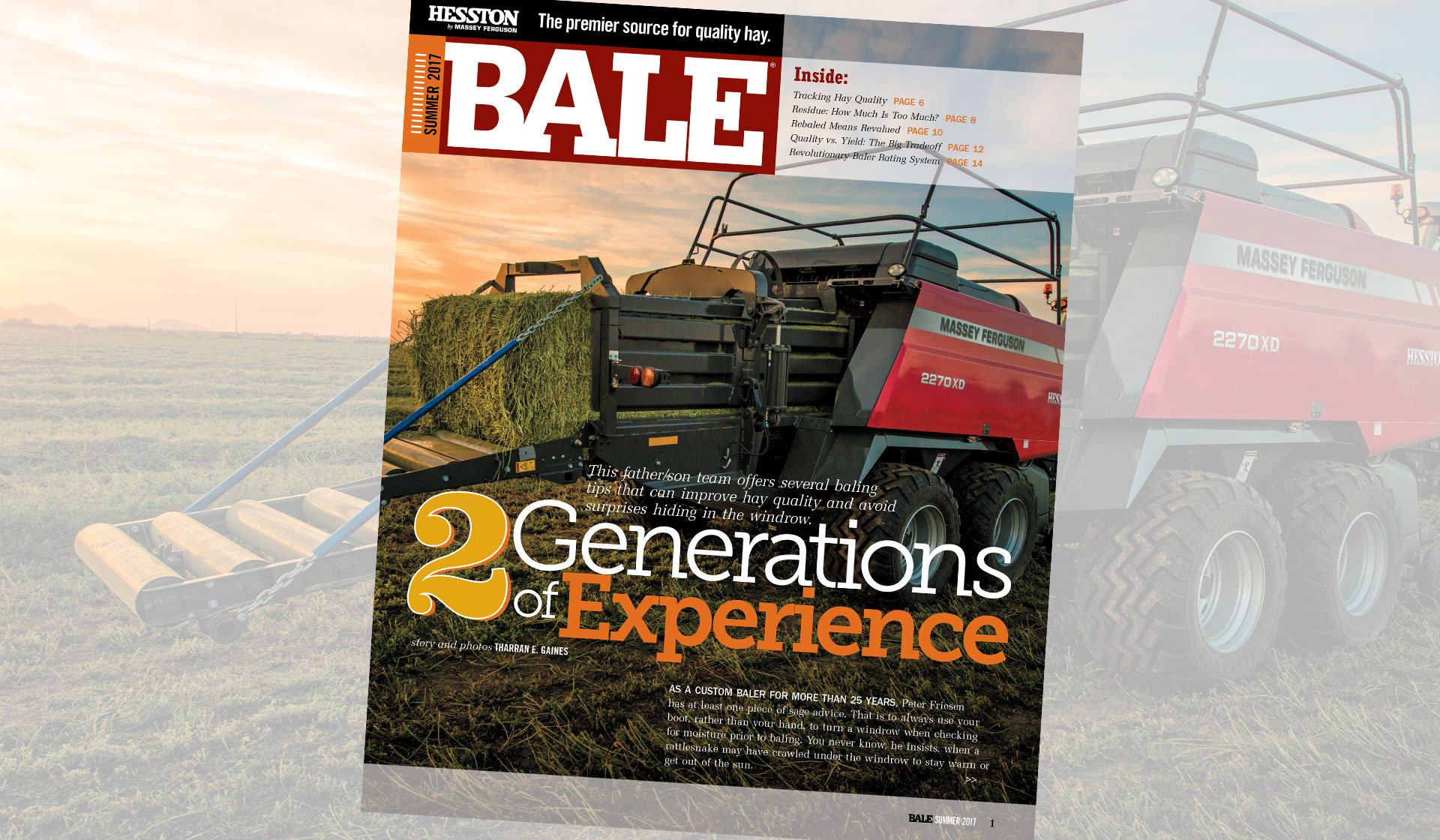

Fortunately, Whitaker no longer has to guess, nor do the dairy employees who feed the cows at the Fallon, Nevada, operation. Prior to last year’s hay harvest, Whitaker had an AGCO HayBoss® G2 RFV (relative feed value) Calculator and RFV Dye Marker Kit installed on the dairy’s Hesston by Massey Ferguson Model 2170XD big square baler. As one of two options for identifying RFV, the dye system sprays each bale with one, two or three stripes of food-grade dye, showing the RFV range of that particular bale. The markings make identification and sorting easier, not to mention much more precise.

“It’s not uncommon to see changes of 30 to 40 points in RFV within the same field,” says Bryant Henningfeld, sales manager for Harvest Tec, the company that manufactures the AGCO HayBoss and related RFV calculator systems. “These wide point swings can affect everything from how the hay is marketed to how it is being fed.

“However, the Dye Marker Kit is just one of the tools available to identify bales based on relative feed value,” Henningfeld adds. “The other is the HayBoss G2 Tagger. This system attaches a vinyl radio frequency identification (RFID) tag around the twine as it passes through the bale chute.”

Welcome Advancement

While the dye system can be used to identify RFV within a close range, the tag can include much more, including a bale identification number; the exact RFV and total digestible nutrients (TDN); the weight of the bale; the field name; date and timing of baling; the average and high moisture of the bale; and the amount of any AGCO® hay preservative applied. If the HayBoss G2 system is equipped with the GPS option, the coordinates of the exact location the bale was tied off in the field will be added. Using this technology, the producer can keep even more detailed records to help maximize productivity in the same manner as a grain farmer who is using yield maps for management decisions.

“The tagger system does, however, require the use of a scanner to read the tag,” Henningfeld explains. “The scanned information can then be downloaded to a USB drive and transferred to a computer and printed, or emailed directly to the end user.”

While Whitaker says he would love to have the G2 Tagger for the extra information the tag provides, he admits that the dye marker system is already a welcome advancement. “Before we cut any hay, I go into the field with a measuring tape and calculate an estimate of the RFV value, based on a standard formula that factors in plant height and maturity,” he says. “These measurements then act as the parameters for the RFV calculator on the HayBoss G2. In other words, I use the field-estimated RFV to set up the range for the dye settings,” he explains.

Lower Cost and Simplicity

The biggest advantage of the dye system, says Henningfeld, is the lower cost and simplicity. While RFID tags alone cost about 69 cents each, $10 worth of dye will cover nearly 200 bales. In order to measure RFV, both the dye and tag systems require the HayBoss G2 main processor with RFV calculating capability, the HayBoss G2 moisture-sensing system, the AGCO bale weight kit or accumulator weight kit, and a compatible monitor. Two 7-inch star wheels, located behind the knotters, measure conductivity across the width of the bale to determine moisture levels from 7 to 70%. Moisture, bale density and bale weight are then combined to calculate RFV via a software program.

“The software was developed based on more than 4,000 bales studied on multiple farms across multiple states,” Henningfeld adds. “As a result, HayBoss G2 calculated values have been within as little as 2% variation of those calculated by a lab.”

Whitaker says that, because of their location in northern Nevada, it can take a week or more to get samples shipped to a lab and receive the results. In the meantime, hay bales need to be quickly off the field, sorted and stacked, making the RFV calculator even more valuable.

“The hay market is driven by quality,” he says. “And even though we use all the hay we produce—and much more—on our own dairy, it’s important that we know the feed value and have the ability to remove those lesser-quality bales from the stack.”